High-Quality Aliphatic Coating Suppliers – SWD8029 two component polyaspartic topcoat – SWD

High-Quality Aliphatic Coating Suppliers – SWD8029 two component polyaspartic topcoat – SWD Detail:

Features and benefits

* the coating film is tough, compact, full light and with bright colors

* no discoloration, no-yellowing, no chalking, anti-aging, with excellent weather resistance and color-preserving decoration effect

* excellent adhesive strength, good compatible with polyurethane, epoxy, chlorinated rubber, alkyd, phenolic and other coating film.

* excellent abrasion resistance, impact resistance

* excellent chemical resistance to acid, alkali, salt and others.

* excellent anticorrosion property

* excellent waterproof property

* excellent durability to reduce lifelong maintenance cost

* extend the service life of the sprayed structure

Application scopes

Anticorrosion protective decoration of various reinforced concrete surface and metal structures, also work as topcoat on aromatic polyurethane and polyurea coating surface.

Product information

| Item | A component | B component |

| Appearance | light yellow liquid | Color adjustable |

| Specific gravity(g/m³) | 1.05 | 1.32 |

| Viscosity (cps)@25℃ | 350 | 320 |

| Solid content (%) | 56 | 85 |

| Mix ratio (by weight) | 1 | 1 |

| Surface dry time (h) | 1-3 h | |

| Recoating interval (h) | Min 3 h; max 24h (20℃) | |

| Theoretical coverage (DFT) | 0.10kg/㎡ film thickness 60μm | |

Typical physical properties

| Item | Test standard | Results |

| Tensile strength(Mpa) | ASTM D-412 | 17 |

| Elongation rate(%) | ASTM D-412 | 300 |

| Abrasion resistance (750g/500r) mg | HG/T 3831-2006 | 5 |

| Impact resistance kg·cm | GB/T 1732 | 100 |

| Anti-aging, accelerated aging 1000h | GB/T14522-1993 | Loss of light<2, chalking <2 |

| The product meets the standard of drinking water materials | GB/T17219-1998 | Pass |

Chemical resistance

| Acid resistance 10%H2SO4 or 10%HCI, 240h | no rust, no bubbles, no peel off |

| Alkali resistance 5%NaOH, 240h | no rust, no bubbles, no peel off |

| Salt resistance 30g/L, 240h | no rust, no bubbles, no peel off |

| Salt spray resistance 1500h | no rust, no bubbles, no peel off |

| Oil resistance, 0# diesel, crude oil | no rust, no bubbles, no peel off |

| Waterproof, 48h | No bubbles, no wrinkled,no color-changing, no peel off |

| (For reference: pay attention to the influence of ventilation, splash and spillage. Independent immersion testing is recommended if requires other specific data.) | |

Processing recommendation

| environment temperature | -5~+35℃ |

| humidity | ≤85% |

| dew point | ≥3℃ |

Application instructions

Hand brush, roller

Air spray, with air pressure 0.3-0.5Mpa

Airless spray, with spray pressure 15-20Mpa

Recommend dft: 30-60μm

Recoating interval: ≥3h

Application tips

Agitate part B uniform prior to application.

Strictly mix the 2 parts in right ratio and agitate uniform.

Seal the package well after use to avoid moisture absorption.

Keep the application site clean and dry, forbidden to contact with water, alcohols, acids, alkali etc

Product cure time

| Substrate temperature | Surface dry time | Foot traffic | Solid dry time |

| +10℃ | 4h | 12h | 7d |

| +20℃ | 2h | 8h | 7d |

| +30℃ | 1h | 4h | 7d |

Note: the curing time is different with environment condition especially when temperature and relative humidity changes.

Shelf life

Storage temperature of environment: 5-35℃

* shelf life is from the manufacturing date and sealed condition

Part A: 10 months Part B: 10 months

* keep the package drum well sealed.

* store in cool and ventilated place, avoid sunshine exposure.

Package: part A: 25kg/barrel, part B: 25kg/barrel.

Product health and safety information

For information and advice on the safe handling, storage and disposal of chemical products, users shall refer to the most recent Material Safety Data Sheet containing physical, ecological, toxicological and other safety related data.

Integrity declaration

SWD guarantee all technical data stated in this sheet are based on laboratory tests. Actual testing methods may vary due to different circumstances. Therefore please test and verify its applicability. SWD does not take any other responsibilities except the product quality and reserve the right of any modifications on the listed data without prior notice.

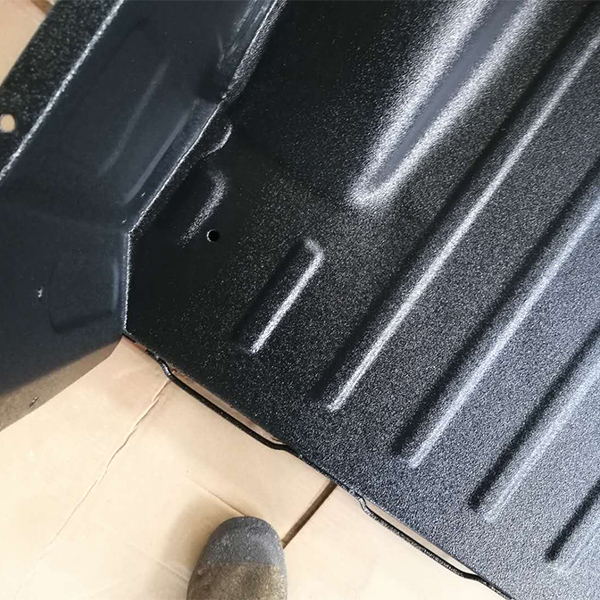

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, trust the first and management the advanced" for High-Quality Aliphatic Coating Suppliers – SWD8029 two component polyaspartic topcoat – SWD , The product will supply to all over the world, such as: France, Birmingham, Los Angeles, Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal goods. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. Detailed data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're going to allow you to get complete acknowledge about our items and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.