High-Quality Polyurea And Polyaspartic Products – SWD8027 polyaspartic abrasion resistance floor coating – SWD

High-Quality Polyurea And Polyaspartic Products – SWD8027 polyaspartic abrasion resistance floor coating – SWD Detail:

Product descriptions

SWD8027 is a two-component material with aliphatic polyaspartic polyurea resin as the main film-forming material, with excellent corrosion resistance, color-change resistance and weather resistance. The product has high solid and low viscosity, good leveling, and meets the requirements of environmental protection; it has excellent workability, can be applied by any application method, and can be cured at low temperature 0 ° C in winter. The coating has excellent flexibility, wear resistance, impact resistance and chemical resistance. It is an ideal weather resistant and environment-friendly floor coating material.

Product application scope

Flooring of city Park Plaza, electronic plant, mechanical factory, chemical plant, pharmaceutical, food and other industrial floors, as well as various outdoor yellowing resistant and wear-resistant floors.

Product information

| Item | A component | B component |

| Appearance | light yellow liquid | Color adjustable |

| Specific gravity(g/m³) | 1.05 | 1.50 |

| Viscosity (cps)@25℃ | 40-60 | 100-200 |

| Solid content (%) | 65 | 88 |

| Mix ratio (by weight) | 1 | 1 |

| Surface dry time (h) | 1 | |

| Pot life (h)@25℃ | 40min | |

| Theoretical coverage (DFT) | 0.15kg/㎡ film thickness 100μm | |

Physical properties

| Item | Test standard | Results |

| Adhesion force (concrete base) | 3Mpa | |

| Pencil hardness | 2H | |

| Bending resistance (cylindrical) | ≤1mm | |

| Abrasion resistance (750g/500r) mg | HG/T 3831-2006 | 5 |

| Impact resistance kg·cm | GB/T 1732 | 50 |

| Anti-aging, artificial accelerated aging | GB/T14522-1993 | Light loss < 1, pulverization < 1 |

Application instructions

Hand brush, roller

Air spray, with air pressure 0.3-0.5Mpa

Airless spray, with spray pressure 15-20Mpa

Recommend dft: 100-200μm (topcoat)

Recoating interval: min 2h, max 24h.

Application tips

Agitate part B uniform prior to application.

Strictly mix the 2 parts in right ratio and agitate uniform.

Seal the package well after use to avoid moisture absorption.

Keep the application site clean and dry, forbidden to contact with water, alcohols, acids, alkali etc

Product cure time

| Substrate temperature | Surface dry time | Foot traffic | Solid dry time |

| +10℃ | 2h | 24h | 7d |

| +20℃ | 1.5h | 8h | 7d |

| +30℃ | 1h | 6h | 7d |

Note: the curing time is different with environment condition especially when temperature and relative humidity changes.

Shelf Life

Storage temperature of environment: 5-35℃

* shelf life is from the manufacturing date and sealed condition

Part A: 10 months Part B: 10 months

* keep the package drum well sealed.

* store in cool and ventilated place, avoid sunshine exposure.

Package: part A: 25kg/barrel, part B: 25kg/barrel.

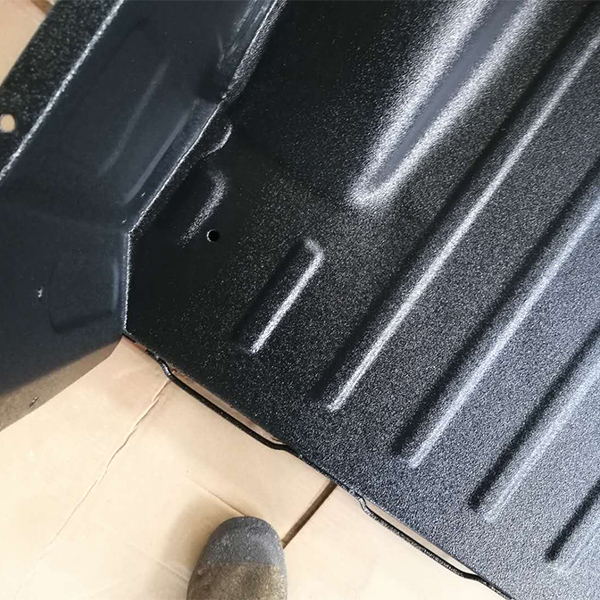

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , now we have our potent staff to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for High-Quality Polyurea And Polyaspartic Products – SWD8027 polyaspartic abrasion resistance floor coating – SWD , The product will supply to all over the world, such as: New Orleans, St. Petersburg, Armenia, we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our products, you can also submit your purchase information online, and we will contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.