High-Quality Spartacote Polyaspartic Products – SWD8027 polyaspartic abrasion resistance floor coating – SWD

High-Quality Spartacote Polyaspartic Products – SWD8027 polyaspartic abrasion resistance floor coating – SWD Detail:

Product descriptions

SWD8027 is a two-component material with aliphatic polyaspartic polyurea resin as the main film-forming material, with excellent corrosion resistance, color-change resistance and weather resistance. The product has high solid and low viscosity, good leveling, and meets the requirements of environmental protection; it has excellent workability, can be applied by any application method, and can be cured at low temperature 0 ° C in winter. The coating has excellent flexibility, wear resistance, impact resistance and chemical resistance. It is an ideal weather resistant and environment-friendly floor coating material.

Product application scope

Flooring of city Park Plaza, electronic plant, mechanical factory, chemical plant, pharmaceutical, food and other industrial floors, as well as various outdoor yellowing resistant and wear-resistant floors.

Product information

| Item | A component | B component |

| Appearance | light yellow liquid | Color adjustable |

| Specific gravity(g/m³) | 1.05 | 1.50 |

| Viscosity (cps)@25℃ | 40-60 | 100-200 |

| Solid content (%) | 65 | 88 |

| Mix ratio (by weight) | 1 | 1 |

| Surface dry time (h) | 1 | |

| Pot life (h)@25℃ | 40min | |

| Theoretical coverage (DFT) | 0.15kg/㎡ film thickness 100μm | |

Physical properties

| Item | Test standard | Results |

| Adhesion force (concrete base) | 3Mpa | |

| Pencil hardness | 2H | |

| Bending resistance (cylindrical) | ≤1mm | |

| Abrasion resistance (750g/500r) mg | HG/T 3831-2006 | 5 |

| Impact resistance kg·cm | GB/T 1732 | 50 |

| Anti-aging, artificial accelerated aging | GB/T14522-1993 | Light loss < 1, pulverization < 1 |

Application instructions

Hand brush, roller

Air spray, with air pressure 0.3-0.5Mpa

Airless spray, with spray pressure 15-20Mpa

Recommend dft: 100-200μm (topcoat)

Recoating interval: min 2h, max 24h.

Application tips

Agitate part B uniform prior to application.

Strictly mix the 2 parts in right ratio and agitate uniform.

Seal the package well after use to avoid moisture absorption.

Keep the application site clean and dry, forbidden to contact with water, alcohols, acids, alkali etc

Product cure time

| Substrate temperature | Surface dry time | Foot traffic | Solid dry time |

| +10℃ | 2h | 24h | 7d |

| +20℃ | 1.5h | 8h | 7d |

| +30℃ | 1h | 6h | 7d |

Note: the curing time is different with environment condition especially when temperature and relative humidity changes.

Shelf Life

Storage temperature of environment: 5-35℃

* shelf life is from the manufacturing date and sealed condition

Part A: 10 months Part B: 10 months

* keep the package drum well sealed.

* store in cool and ventilated place, avoid sunshine exposure.

Package: part A: 25kg/barrel, part B: 25kg/barrel.

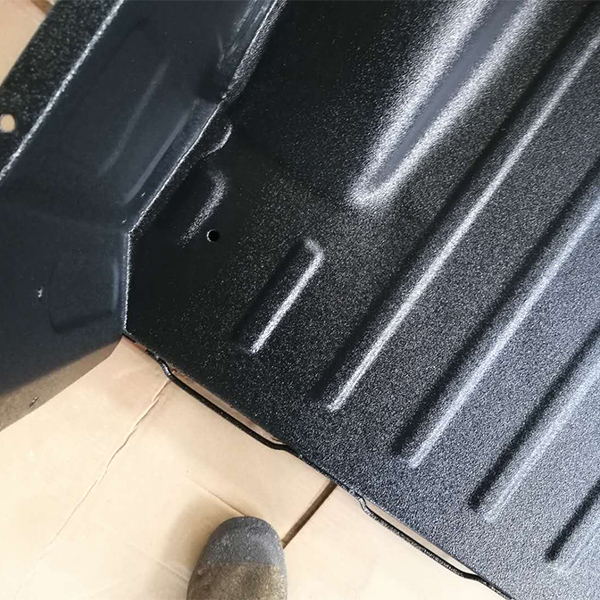

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and together with the top-quality good quality solutions, favorable selling price and superior after-sales providers, we try to acquire each customer's rely on for High-Quality Spartacote Polyaspartic Products – SWD8027 polyaspartic abrasion resistance floor coating – SWD , The product will supply to all over the world, such as: Malawi, Anguilla, panama, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to offer you good quality products and the best service. We are looking forward to serving you.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.