Low Pressure Spray SWD562 cold spray polyurea elastomer anticorrosion waterproof abrasion resistance coating – SWD

Low Pressure Spray SWD562 cold spray polyurea elastomer anticorrosion waterproof abrasion resistance coating – SWD Detail:

Characteristics

Cold polyurea is applied with a simple spray gun, easy to apply, one person can operate it. It can be directly sprayed in the temperature above 25℃, use a microwave to heat the liquid material to 35℃ if the environment temperature below 25℃. The curing time is adjustable from 2-10 min, can be sprayed forming on any curve, vertical or slope surface, without sagging. The coating is flexible, compact and seamless, with excellent comprehensive physical properties, no powdery, no peel off or crack after long term outdoor use, it is resistant to any cold & hot impact and weather changing corrosion.

Application scopes

Wearable anticorrosion protection of coal chute, spiral separator, flotation tank, washing drum, transmission belt and other mining facilities.

Specifications

| Adhesive strength (concrete base) | ≥2.9Mpa( or substrate broken) |

| Adhesive strength (steel base) | ≥8.5Mpa |

| Tear strength | ≥70kg•cm |

| Tensile strength | ≥15.0Mpa |

| Elongation | ≥400% |

| Penetration resistance | 2.1Mpa |

| Temperature variation resistance | -50——+120℃ |

| Wear resistance (750g/500r) | ≤10mg |

| Acid resistance 10%H2SO4 or 10%HCI, 30d | no rust no bubbles no peel off |

| Alkali resistance 10%NaOH, 30d | no rust no bubbles no peel off |

| Salt resistance 30g/L, 30d | no rust no bubbles no peel off |

| Salt spray resistance 1000h | no rust no bubbles no peel off |

| Oil resistance 0# diesel crude oil 30d | no rust no bubbles no peel off |

Data of performance

| Color | Multiple colors as customers’ need |

| Luster | glazed |

| Density | 1.01g/cm3 |

| Volume solid content | ≥98% |

| VOC | 0 |

| Recommended dry film thickness | 500-3000μm |

| Theoretical coverage | 1.02kg/sqm (calculated by the above solids percentage and dry film thickness of 1000 microns) |

| Practical coverage | Allow appropriate loss rate |

| Surface dry time | 3-5min |

| Re-coating interval | ≤ 6h (20℃) |

| Re-coating method | two component air sprayer |

| Mix ratio | A:B=1:1 (by volume) |

| Normal package | 1.6kg/set (part A: 0.82kg, part B: 0.77kg) |

| Application temperature | 25-40℃ (use a microwave to heat the material to 35℃ when apply in cold weather) |

| Flash point | 200℃ |

Recommend procedures

|

No. |

Name of products |

Layers |

Dry film thickness(μm) |

|

1 |

SWD polyurea special primer |

1 |

35 |

|

2 |

SWD562 cold polyurea elastomer |

1 |

2000 |

|

Total |

|

2 |

2050 |

Product application environment

| Environment temperature | 0℃-45℃ |

| Product spray heating temperature | 65℃-70°C |

| hose heating temperature | 55℃-65℃ |

| Relative humidity | ≤90% |

| Dew point | ≥3℃ |

Shelf life

10 months (Indoor with dry and cool conditions)

Packing

1.6kg/set (part A: 0.82kg, part B: 0.77kg)

Production places

Minhang Shanghai City, and Nantong coastal industrial park production base in Jiangsu (15% of the raw materials imported from SWD US, 40% from multinational company in Shanghai, 45% from local support)

Security

To apply this product must be accordance with the relevant national regulation of sanitation, safety and environment protection. Do not even contact the surface of wet coating.

Global applicability

Our company aims to provide worldwide customers with standard coating products, however custom adjustments can be made to adapt and leverage different regional conditions and international norms. In this case, additional alternative product data will be provided.

Integrity declaration

Our company guarantees the reality of the listed data. Due to the diversity and variability of the application environment, please test and verify it before use. We don’t take any other responsibilities except the coating quality self and reserve the right of modifying the listed data without prior notice.

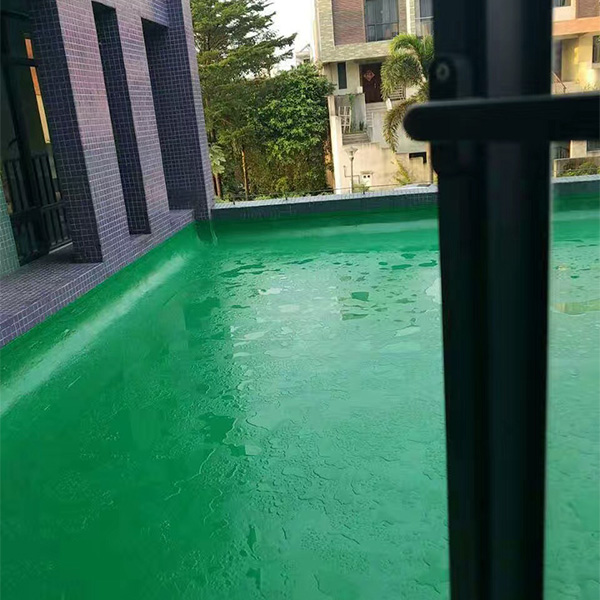

Product detail pictures:

Related Product Guide:

We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Low Pressure Spray SWD562 cold spray polyurea elastomer anticorrosion waterproof abrasion resistance coating – SWD , The product will supply to all over the world, such as: Buenos Aires, Curacao, Malta, We are seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.